In general, designers do not reinvent the propeller with every project. Several standard propeller series have been developed for selection. A designer typically selects a standard series that best matches the propeller’s application. They may slightly modify the propeller design, but most propellers remain close to one of the standard series designs.

What does a standard series entail? It’s all about the blade shape and experimental testing. Each standard series consists of a set of propeller sizes based on a single geometric pattern. Each series includes variations in diameter, blade area, and pitch. Some even account for skew variations. The key point is that each series has been tested in a laboratory to determine its precise performance characteristics. Here are some possible names you might encounter when referring to propeller series:

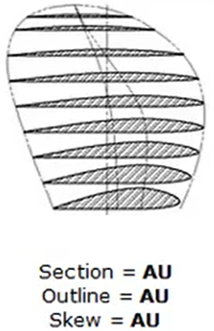

AU Series

This series can be considered the most common and widely used series of marine propellers, employed in many marine vessels and equipment. Below are the detailed specifications of this series:

These propellers are of the open-wheel type, meaning they lack a shroud (covering at the blade tip).

The blade section resembles an airfoil, similar to aircraft wings.

The maximum thickness of the airfoil section at the root is at 32% of the chord length from the leading edge.

The maximum thickness of the airfoil section at the tip is at 50% of the chord length from the leading edge.

The skew of this blade is balanced and symmetrical.

The root diameter ratio for this series is [value not specified].

AU CPP Series

This series is identical to the AU series, with the difference that it has the capability to change the pitch of the blades connected to the hub. In other words, the only difference, which gives this propeller an advantage over the AU series, is the ability to adjust the propeller pitch.

This model is very similar to the B-series propellers, with the difference that the hub surface is flat and smooth.

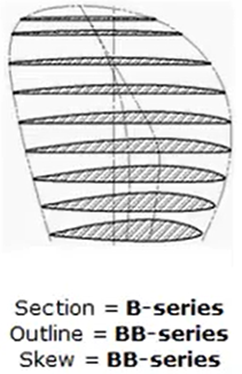

B-Series

This series, like the AU series, is very common and widely used in many marine vessels. Some specifications of this series are as follows:

These propellers are of the open-wheel type, meaning they lack a shroud.

The blade section resembles an airfoil.

The maximum thickness of the airfoil section at the root is at 35% of the chord length from the leading edge.

The maximum thickness of the airfoil section at the tip is at 50% of the chord length from the leading edge.

The skew of this blade is balanced and symmetrical.

The root diameter ratio for this series is [value not specified].

BB-Series

This series is similar to the B-series. However, the available information is limited, but the BB-series profiles are similar to those of the B-series.

These propellers are of the open-wheel type.

The blade section is similar to the B-series.

The maximum thickness of the airfoil section at the root is not specified.

The maximum thickness of the airfoil section at the tip is not specified.

The skew of this blade is balanced and symmetrical.

The root diameter ratio for this series is the same as the B-series [value not specified].

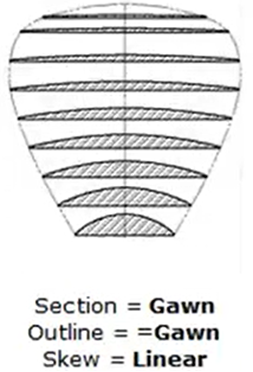

Gawn Series

This series is used in many marine vessels. Some specifications of this series are as follows:

These propellers are of the open-wheel type, meaning they lack a shroud.

The blade section has a flat face and a curved (circular) back.

The maximum thickness of the section at both the root and tip is at 50% of the chord length from the leading edge.

The thickness of the leading and trailing edges is equal to the thickness of the propeller tip.

This series has no skew angle, meaning the skew angle is zero.

The root diameter ratio for this series is [value not specified].

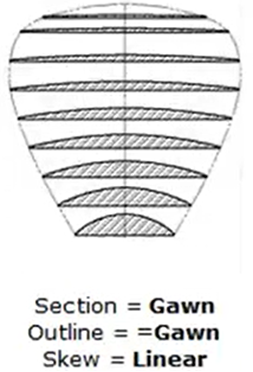

Modified Gawn Series

Some specifications of this series are as follows:

These propellers are of the open-wheel type, meaning they lack a shroud.

The blade section has a flat face and a curved (circular) back.

The maximum thickness of the section at both the root and tip is at 50% of the chord length from the leading edge.

The thickness of the leading and trailing edges is equal to the thickness of the propeller tip.

The face of the Modified Gawn series sections has a circular curve, which is the geometric difference from the Gawn series (the Gawn series face is flat and smooth).

The reason for using a circular curved face in these propellers is to create more clearance between the blades, which reduces pressure on the pressure side of the blade, resulting in reduced local thrust without altering the structural characteristics of the blade root.

This series has no skew angle, meaning the skew angle is zero.

The root diameter ratio for this series is [value not specified].

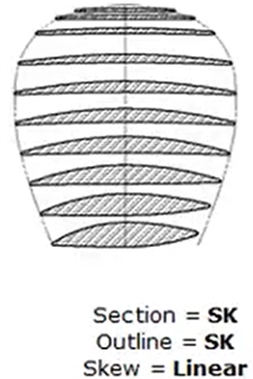

SK Series

This series is used in many marine vessels, particularly in Russian-built vessels. Some specifications of this series are as follows:

These propellers are of the open-wheel type, meaning they lack a shroud.

The blades have a curved section and a progressive pitch.

The number of blades in this propeller is three.

The maximum thickness of the section at both the root and tip is at 50% of the chord length from the leading edge.

This propeller performs well in high-speed vessels.

The root diameter ratio for this series is [value not specified].

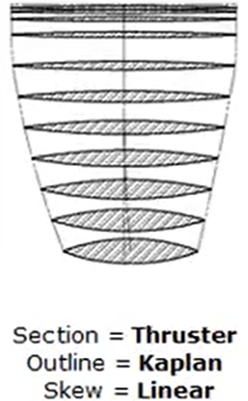

Kaplan Series

This series is used in several types of marine vessels. Some specifications of this series are as follows:

These propellers are of the close-wheel type, meaning they have a shroud (covering at the blade tip), also known as ducted propellers.

The maximum thickness of the section at the root is 50%, and at the tip, it is 35% of the chord length.

This series has no skew angle, meaning the skew angle is zero.

The root diameter ratio for this series is [value not specified].

Thruster Series

This series is used in several types of marine vessels. The curvature of this series is very similar to the Gawn series. Some specifications of this series are as follows:

These propellers are of the close-wheel type, meaning they have a shroud, also known as ducted propellers.

The maximum thickness of the sections at both the root and tip is 50% of the chord length.

This series has no skew angle, meaning the skew angle is zero.

These sections are completely symmetrical in terms of chord length and thickness and are developed based on a circular curve, similar to the Gawn series.

These sections are generally used for propellers with variable rake angles.

As evident, the list of propeller series is extensive. Each series has its own strengths and weaknesses. What a propeller designer needs is to understand the subtle differences between each series.

The designer must first select the appropriate propeller series based on the vessel and its operational conditions. Most propeller series have been tested for a range of conditions. They do not cover the entire range of speeds and performance desired by designers. Therefore, a designer eliminates any series that does not meet the basic requirements early in the process. Often, one to three options remain. At this point, a simple comparison between the different options is made to determine which design best suits the designer’s requirements, considering the advantages and disadvantages of each.